From gelatine to membrane

Clear and transparent, that's how most people like certain juices, such as apple, blackcurrant or cherry. But fresh from the press, every juice is naturally cloudy. It must first be "clarified" - i.e. the tiny solid particles, plant proteins and enzymes, must be extracted. They used to use gelatine for it. The solid particles bind well to this, making them easy to remove.

But gelatine is of animal origin. That was and is problematic for many people and cultures. The method was also not perfect because small amounts of residue could still remain in the juice. This could lead to a slight cloudiness arising in the juice during remixing in the bottling plant

It was not until the mid-1980s that a filter system came onto the market that was fine enough to mechanically clarify fruit juices: ultrafiltration. "We immediately wanted it! " remembers Erich Rauch. In 1985, he and his team spent several weeks testing systems from three manufacturers in a test facility in the company's basement. "We pumped thousands of litres of juice through the filters. We tested how precisely the systems worked and also, how easy they were to use in everyday working life." In 1986, the first ultrafiltration plant went into operation in the production hall in Rankweil

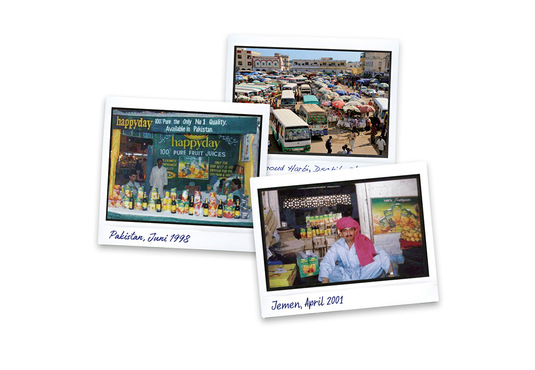

Thanks to this modern filtration technique, clear Rauch juices are completely free of animal ingredients and meet the highest religious and ideological standards: halal, kosher and vegan.

There are also standards for the colour of apple juice. These are determined by comparison with colour samples like these.

But for apple juice to shine, it must be clarified. Since 1986 Rauch has been using modern filtration technology to achieve this, instead of gelatine.