Sure, we can do cans.

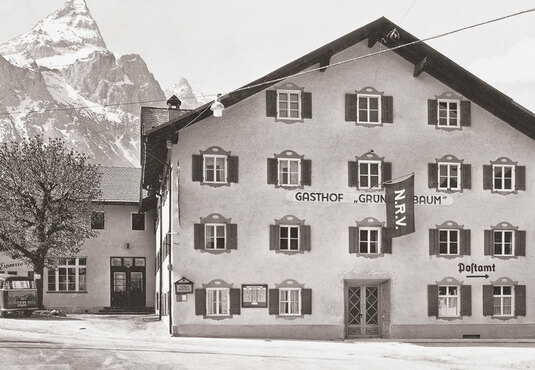

"Can you do cans?" That was the most important question Roman Rauch heard during a visit to Saudi Arabia in 1976. Japanese fruit juice manufacturers had recently introduced this new, practical packaging ... and cans of juice were excellent sellers. Rauch's answer was: "Sure!"

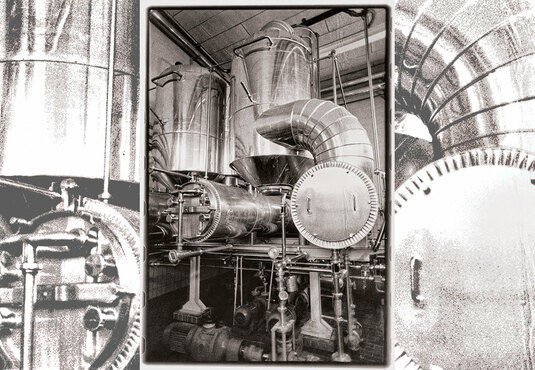

"There was only one catch," remembers Erich Rauch. "At the time, all bottlers wanted cans. The manufacturers' waiting lists were unsurprisingly long." So the technicians started looking for a second-hand plant. They found it at a brewery in Bavaria.

"They were waiting for their new plant. As soon as it was running, we could take over their old one. 3,000 cans per hour." When it was finally time, Erich Rauch got in the truck with Albert Sonderegger and picked up the system personally. "Dismantled, it all fitted on two pallets. They somehow installed the can filler into an existing bottling line. Although this old system regularly required the maintenance technicians, the goal was achieved: Rauch could now also do cans.

They quickly became a hit in Arab countries. Just one year later, Rauch put the next, more modern plant into operation - doing 10,000 cans per hour. By the way: 120,000 cans come off the production line every hour on our current can lines.

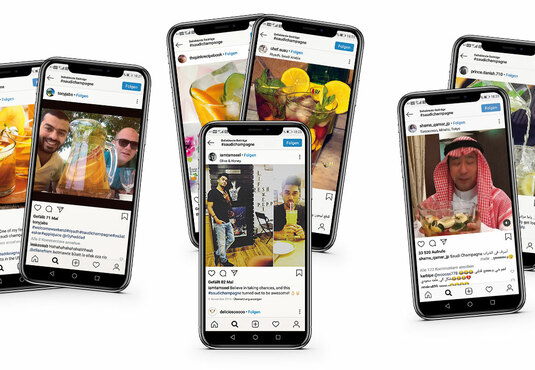

Rauch juices are still bestsellers in North Africa and Arabia ... and therefore also popular with product pirates: all these cans are fakes. Rauch is the Rolex watch of juices.